Ultimate Welding Career Guide

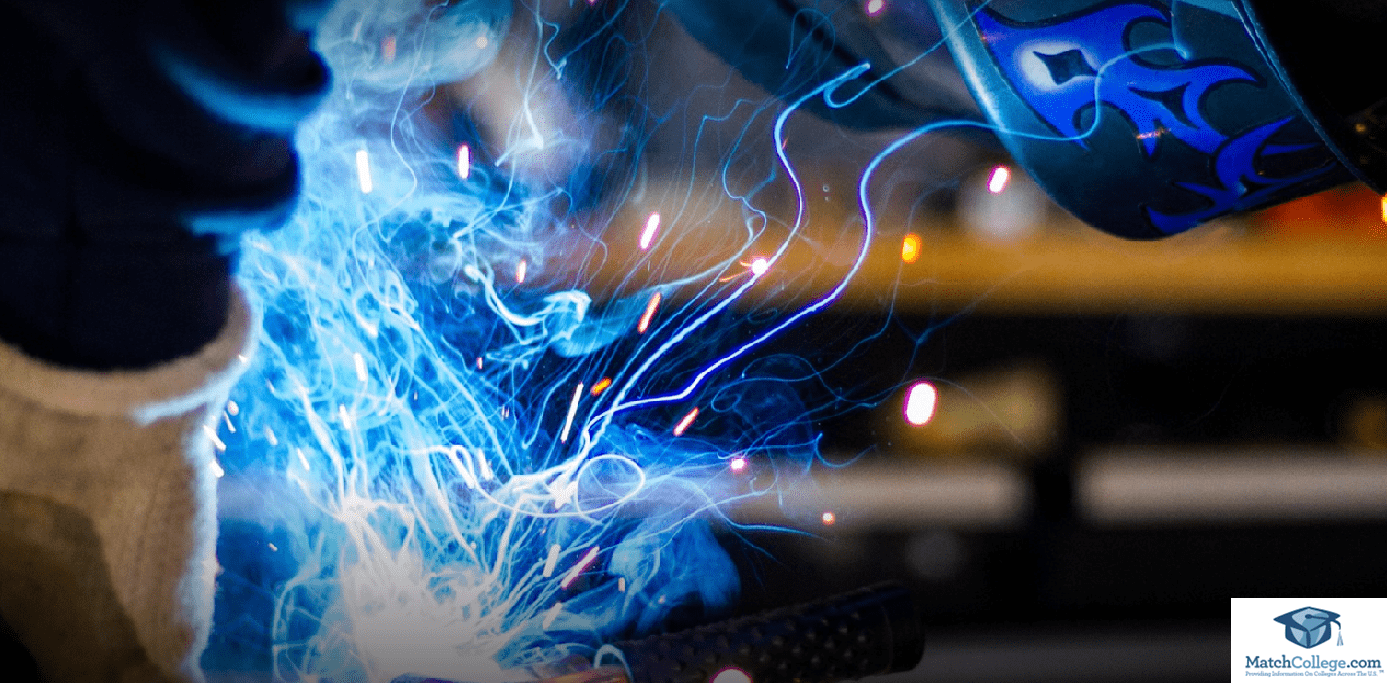

Welding Career Overview

A welding career can be a viable, long-term trade for individuals of all backgrounds. You may be surprised to learn how expansive the welding industry really is. From skyscrapers to automobiles to bridges and beyond – welding is an important profession that markedly affects people, corporations, and communities on a daily basis. In fact, data gathered by the American Welding Society (AWS) affirm that nearly half of the country’s total gross national product consists of welding work, welded products, and other related welding services.

Where Do Welders Work?

You may be amazed to learn that a welding career is quite different than most people may imagine. In fact, welders work everywhere from deep beneath the surface of the sea surface to the far reaches of a space station in orbit to the top of the world’s tallest buildings. The roles within the welding profession can be dynamic and stimulating. A career in welding can offer an array of rewarding opportunities to students and professionals who deftly harness industry-specific knowledge, understand scientific principles, and successfully apply the most advanced welding technologies.

Most Popular Welding Applications

As you have gathered thus far, anything made from metal can be welded. Common examples of metallic items that are welded include cars, trucks, motorcycles, rail cars, rockets, ships, aircraft, offshore oil platforms, solar panels, wind turbines, natural gas pipelines, and space stations. The construction industry is a vast market and suffice it to say the skyscrapers, highways, and bridges we use every day would be impossible to construct without welding. Welders also help to install and maintain antipollution systems, boilers, and other large industrial structures.

In addition to the commercial and residential applications, welding is often used in art. More specifically, welding is often used by artists to make sculptures and other decorative items by taking disparate pieces of metal to create something wholly new and different.

Technology Advancements in Welding

Welding technology has dramatically transformed in the past two decades and has shifted the profession’s demographics accordingly. More specifically, in the recent past we have seen younger, more technology-oriented students gravitating to the welding vocation.

You can readily see this demographic shift on display at worksites where teams routinely work with robotics, lasers, computer aided programming, and many other complex technologies to aid the welding process. To support this shift in the field, welders are receiving greater support and information from associated disciplines such as certified inspectors, engineers, and a specialized sales team.

There is seemingly no limit to what welders can do, particularly since advancements in technology persistently improve the quality, accuracy, and versatility within this discipline. Welding is a progressive, high-tech skill that has been a vital part of our country’s rich history and will continue to be an important trade in the future.

As further evidence of the progressive nature within the welding trade, it is important to know that welders in various industries are being trained to program and control robots and automated systems to leverage electron beams, powerful lasers, and explosives to bond metals. Welding trades of the future will continue to work with computer systems and program software to make the welding process more efficient and safer for a variety of associated professionals.

Job Demand for Welders

From manufacturing to car racing to construction, there is a strong demand for welders, cutters, solderers, and brazers. Salaries can be very competitive taking into account the education level requirements and technical skills requisite by position. The average wages across the welding industry are in excess of $18 per hour with some cities in excess of $34 per hour, with more multifaceted roles such as underwater welding, boilermakers, professionals holding a specialized certification, and supervisory roles garnering a much higher level of compensation.

Presently, the markets with the highest demand for welders are Alaska, Texas, Hawaii, North Dakota, Wyoming, New Mexico, Nevada, Washington, the Gulf States, New Jersey, and Washington D.C.

A Career in Welding

Don Howard, welding professional at Concurrent Technologies Corp in Johnstown, PA, approximates that nearly a quarter of welding in the United States is computerized and predicts this trend can grow another 20% in a the coming decade. Howards adds that “a lot of intelligent individuals are entering into the welding community.”

While there is a lot of money to be made as a welding professional, the welding industry offers a wide array of career paths to support long term growth and stability. The welding industry is no longer a trade to be performed on a manufacturing line; rather, through the use of technology and higher education, welders from a variety of backgrounds can find challenging, meaningful work in a number of niches.

Most Popular Types of Welding

With over 80 different welding processes, it is important to understand the different types and methods. The clustering of different welding can be grouped into five main buckets: oxyfuel gas welding, arc welding, resistance welding, solid-state welding, and specialized welding.

Oxyfuel Gas Welding. The oxyfuel gas welding process uses fuel gases such as acetylene, gasoline, hydrogen, MPS, propylene, and/or butane with oxygen to both weld and cut materials. A few of the types of welding processes include: pressure gas welding, oxyhydrogen welding, oxyacetylene welding, air acetylene welding, and oxygen-propane welding.

Arc Welding. Arc welding uses a welding power source to create an electric arc between the base metal and the wire/electrode stick to melt the base metal(s) where they are to be bonded together. Examples of arc welding include: flux cored arc welding, carbon arc welding, bare metal arc welding, atomic hydrogen arc welding, gas metal arc welding, plasma arc welding, gas tungsten arc welding, shielded metal arc welding, magnetically impelled arc welding, and submerged arc welding.

Resistance Welding. Resistance welding is a high speed process of joining metals that combines electrical heat with pressure for a specific time to hold materials together. Types of resistance welding include: resistance seam welding, resistance spot welding, flash welding, upset welding, low frequency electric resistance welding, and projection welding.

Solid-State Welding. Solid-state welding is a process that bonds base materials together by heating them below their respective melting points without the use of additional brazing filler materials. Examples of solid-state welding are: hot pressure welding, hot isostatic pressure welding, roll welding, ultrasonic welding, coextrusion welding, diffusion welding, cold pressure welding, explosion welding, friction stir welding, forge welding, and electromagnetic pulse welding.

Specialized Welding. The remaining types of welding to not neatly fit within a category and are grouped together within the specialized welding processes. A few welding processes within specialized welding include: stud arc welding, electron beam welding, electrogas welding, thermite welding, electroslag welding, flow welding, induction welding, laser beam welding, percussion welding, and laser-hybrid welding.

Education Requirements for Welders

A lot of students are introduced to high-tech aspects of the welding trade through a new educational process known as virtual welding. In essence, virtual welding is a simulation program developed by Edison Welding Institute to teach the basics of the welding profession to students in a classroom setting.

The core objective with virtual welding is to give students a simulated welding experience as a supplement to the academic training provided. The pairing of academic theory with virtual reality is a powerful learning tool for a broad number of students.

In order to be considered for most welding jobs, you will need to successfully complete an associate degree, bachelor’s program, or certificate program from an accredited higher education institution. To learn more about certificate programs and degrees within the welding trade, visit our welding page today.

Why a Career in Welding?

As you have seen, the influence of welding is very broad with an array of applications worldwide. As the demand for skilled welders rises coupled with rapid advances in welding technology, welding professionals and students will continue to have a growing opportunity to pursue a career geared towards niche interests.

Why you select a career in welding will wholly be a personal decision. Commit to become the very best you can be by finding the perfect welding college degree for you with your trusted partner MatchCollege and research a full list of top ranked colleges from around the country in a single search.